2 curing unsaturated polyester and vinylester resins with organic peroxides accelerators and other additives introduction this technical bulletin deals with the use of organic peroxides for curing of unsaturated polyester resins and.

Vinyl ester ppt.

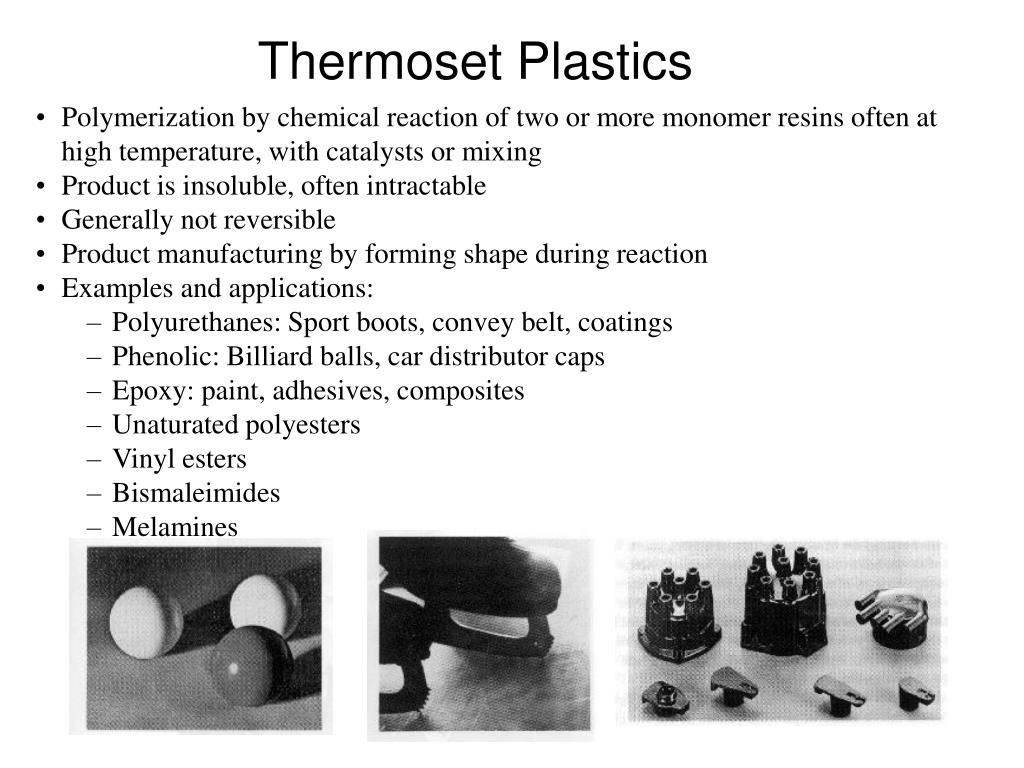

Vinyl ester resins are a type or subset of polyester resin.

The experimental values from this research correlated well with results from rule of mixtures in in plane direction and also correlated with other theoretical methods.

Neat vinyl ester resin increased the conductivity by nearly 88 170 respectively.

Novolac vinyl ester market to grow at 6 cagr till 2025 more information https bit ly 2dd5ehs marine applications are estimated to contribute a share close to 20 in global vinyl ester market by 2025.

Freezer vinyl ester prepregs can be stored at room temperature.

The marine industry involves product usage as gel coats barrier coats etc.

The results of this research.

In comparison the molding time is 10 minutes for the epoxy carbon system that iacmi.

Bisphenol a and novolac epoxies generally are used.

Vinyl ester ceilcote 380 primer is a catalysed vinyl ester primer.

It provides excellent bonding and adhesion for various polyester and vinyl ester linings coatings and flooring systems as well as for ceilcote hybrid polymer systems.

Polyester and vinyl ester resins resin pre polymer oligomer 40 to 100 typically 55 65 provides polymer properties including modulus toughness glass transition temperature and durability.

The polyester resin is strengthened by the addition of epoxy resin.

Vinyl ester is used as a resin which is a hybrid form of polyester resin.

Uses ceilcote 2 hardener.

Reactive diluent or monomer styrene commonly 0 60 typically 35 45.

O fast cure 3 minutes.

The best peroxide for standard vinyl ester application trigonox 239 cumene hydroperoxide promoter high reactive low peak exotherm in thick layers a must for vinyl ester gelcoats at room t only suitable in vinyl ester resins the best peroxide in case no gassing is allowed trigonox k 90 cumene hydroperoxide low reactive.

The prepreg surrogates made in this project were compression molded at 325 350of and 100 psi pressure and a molding time of 3 minutes.