Portable dockboards are secured by anchoring them in place or using equipment or devices that prevent the dockboard from moving out of a safe position.

To safely handle portable dockboards use.

This includes checking for any signs of damage including cracks missing nuts or bolts faulty locking legs span locks or disfigured side curbs.

Ensure the dockboard is centered when in use.

Because they are designed to support heavy equipment they are quite heavy.

The biggest element of dock board safety is transportation and handling.

Inspect your dockboard thoroughly to insure it s safe to use.

Portable hand truck dock boards are ideal for bridging gaps between the backs of trucks and docks.

When the employer demonstrates that securing the dockboard is not feasible the employer must ensure there is sufficient contact between the dockboard and the surface to prevent the dockboard from moving out of a safe position.

Workplace facilities must have an effective method to secure dockplates or anchor them in place while in use.

Dockboards are engineered and built to safely handle heavy forklifts and loads.

Prepare the loading area.

Never try to lift skids and pallets alone.

A worker should never try and move a dock board by themselves.

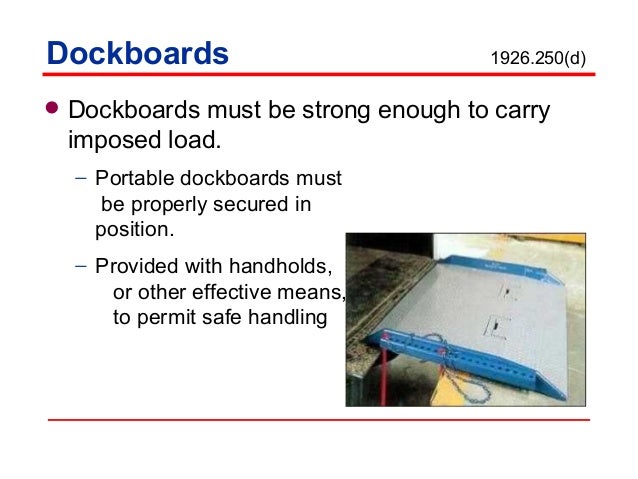

1917 124 c 3 hand holds or other effective means shall be provided on portable dockboards to permit safe handling.

This is to prevent a vehicle from moving or shifting the portable dockplate out of place while driving over it.

Capacities from 5 000 lbs.

Locking legs are uneven to allow the dockboard to sit canted for easier pickup by forklifts when picking off the floor.

Portable dockboards shall be anchored in position or be equipped with devices to prevent their movement.

Portable dockplate requirements have also been updated.

Dock plates are considerably easier to move.

Report incidents and equipment concerns to supervision immediately.

Use forklifts dollies and other aids or get help rather than lifting by yourself whenever possible.

They allow you to safely use forklifts and other power equipment when moving heavy loads to and from your loading dock.

Wear snug fitting gloves that provide good grip when lifting loading and unloading.

They feature aluminum construction with steel bolt on legs to prevent dock boards from slipping while in use.

Return the dockboard to the appropriate storage location away from egress paths exits and working areas.

Upon completion remove the dockboard using proper lifting techniques handholds or lifting aids forklifts as applicable.

We at a plus warehouse sell aluminum and steel boards with bolt on or welded curbs.

Punched design helps to withstand increased traction.

Locking legs prevent movement during loading and unloading.